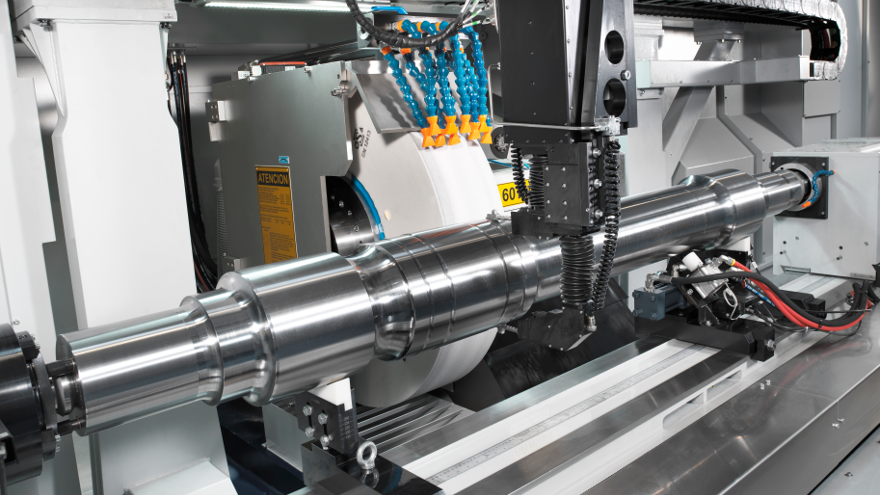

High-Speed Rail Axle Manufacturing

Our solution

- The world’s most advanced railway axle manufacturing line, both in terms of the complexity of the system, the totally integrated automation, and the variety of innovative solutions on each individual machine.

- Automated line for high-speed train axles which ensures the high precision and quality that these components require.

- Turnkey line for the manufacturing and verification with high flexibility.

- Simulation and modelling of the complete facility in order to validate the yearly throughput before execution of project. (Bottle neck analysis, load analysis, simulation of yearly production mix etc).

Previous machining process

- Yearly throughput limited by the number of manual processes.

- High wastage quantity.

Advantages

- Optimisation of previous machining processes.

- Personalised CAM system for part programing.

- All processes are verified offline, guaranteeing 100% machining efficiency.

- Increased productivity through reduced set up times.

- Quality guaranteed.

- Production times are shorter than previous process.

- Higher efficiency in human resources usage.

- Reduced amount of manual handling operations; higher health and safety conditions.

- Less wastage.

- Highly repeatable accuracy.

Installation Consists of

- Axle identification and automatic loading unit.

- Machining: turning, rolling and grinding.

- Measurement.

- Ultrasonic and magnetic particle inspection.

- Robotic system for axle handling.

- Modular and customised line control system (traceability, alarm, planning, etc).